[email protected]

[email protected]

+86 181-5747-1135

China Rubber Cable Manufacturers wholesale Rubber Cable Factory

+86 181-5747-1135

China Rubber Cable Manufacturers wholesale Rubber Cable Factory

Established in 1998, Zhejiang Jiahui Wire And Cable Co.,Ltd is a professional China Rubber Cable Manufacturers. To provide customers with best service and guarantee products quality, we are using advanced ERP, MES and SAP for all incoming and outgoing data management. As a professional wholesale Rubber Cable Factory, Our factory devotes to producing Rubber Cable, automotive wire, power cable and high temperature wire etc. We also get certification of UL,CE,VDE,TUV,SAA,CCC,GS etc. and all our products comply with ROHS and REACH environment standard.

More than 22 years of industry experience

Covers an area of 30,000 square meters

More than 200+ employees

Our annual production capacity is over 500,000km/year.

High Performance Production Machine,7S Site Management , Precise Laboratory Equipment

The operating temperature range of this aluminum conductor PVC coated automotive wire is from -40°C to +125°C, covering a wide range of temperatures f...

UL3122 Silicone Fiberglass Braiding Wire, as a wire product designed for high-performance applications, has a core material for its insulation layer m...

The application of XLPE insulation in automotive wires has shown significant advantages in many aspects compared with other insulation materials. Thes...

Teflon cables are mainly suitable for a variety of applications that require high temperature resistance, corrosion resistance, and good insulation pe...

VDE H05SJ-K Fiberglass Silicone Wire, as a high-performance wire material, play an important role in the internal wiring of many fields and types of p...

The "PI film + white silk" type design plays a vital role in the manufacture of Silk Cover Stranded Enameled Magnet motor winding wire high frequency ...

Flexibility and Durability Unite: Exploring the Advantages of Rubber Cables

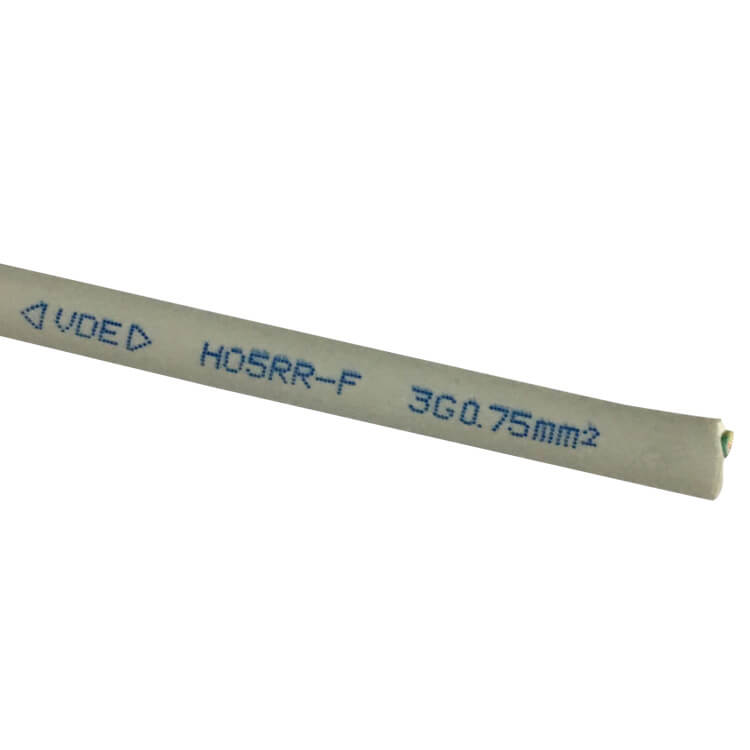

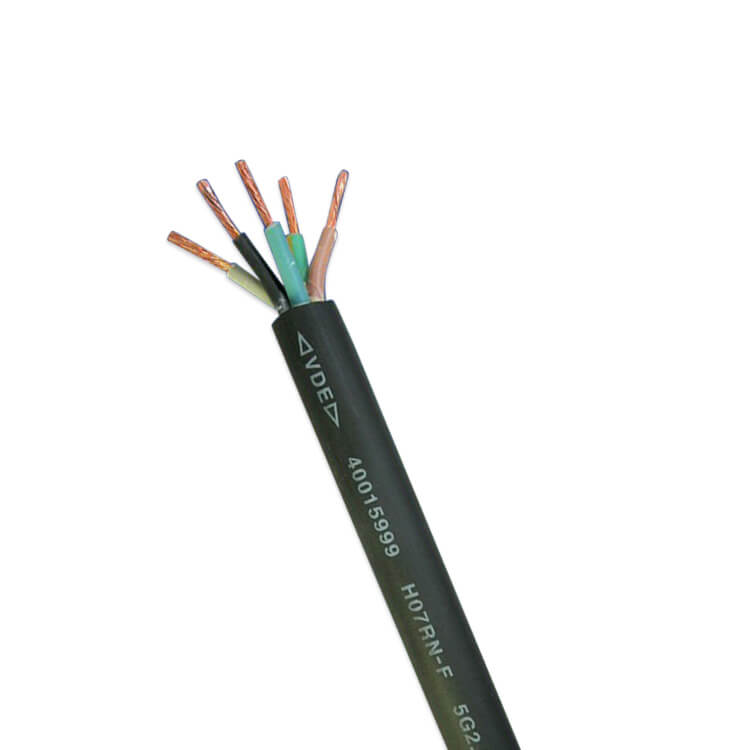

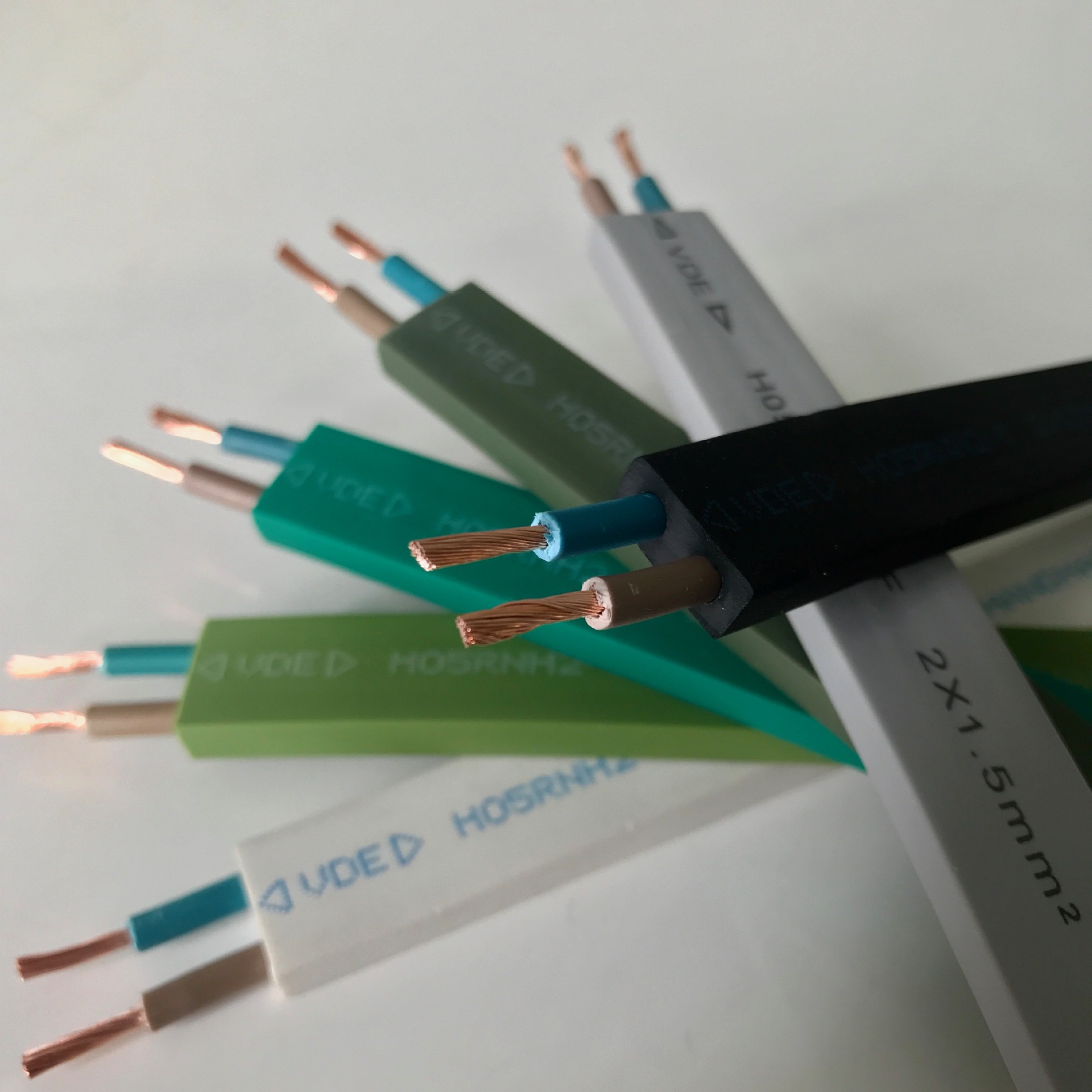

In the realm of electrical cabling, rubber cables have emerged as a versatile and indispensable asset. These cables, encapsulated in robust rubber or elastomeric insulation and sheathing, offer a unique amalgamation of flexibility and durability that is highly valued across various industries. In this exploration, we delve into the manifold advantages that rubber cables bring to the table, shedding light on the attributes that make them a preferred choice in diverse applications.

At the heart of rubber cables lies their exceptional flexibility, a characteristic derived from the innate elasticity of the rubber insulation and sheath. This remarkable pliability enables rubber cables to seamlessly navigate through intricate paths, negotiate tight corners, and adapt to complex layouts. This feature proves invaluable in scenarios where cables need to remain mobile, such as in robotics, automation, and portable equipment. Unlike rigid counterparts, rubber cables effortlessly accommodate dynamic environments, ensuring uninterrupted signal and power transmission.

Durability is a hallmark trait of rubber cables, fortified to withstand the harshest conditions. Impervious to extreme temperatures, moisture, chemicals, and UV radiation, rubber cables exhibit a remarkable resilience that prolongs their operational lifespan. This robustness makes rubber cables well-suited for applications demanding sustained performance despite challenging external factors.

The mechanical tenacity of rubber cables is a testament to their design integrity. Engineered to resist abrasion, impact, and mechanical stress, these cables excel in environments prone to wear and tear. This resilience is particularly crucial in scenarios involving proximity to sharp edges, abrasive surfaces, or heavy machinery, where cable integrity must be preserved for safety and performance.

Rubber cables also exhibit noteworthy thermal versatility, able to function efficiently across a broad range of temperatures. This adaptability equips them for outdoor installations and industrial settings where temperature fluctuations are the norm. By weathering extreme conditions, rubber cables ensure consistent functionality and prolonged service life.

A distinctive quality of rubber cables is their resistance to chemical aggression. The composition of rubber insulation and sheathing provides an effective barrier against oils, solvents, acids, and other corrosive substances. This resistance is highly beneficial in industries such as manufacturing, petrochemicals, and mining, where exposure to chemicals is commonplace.

Rubber cables excel as electrical insulators, safeguarding against electrical interference and signal degradation. This makes them integral to power distribution, machinery operation, and electronic equipment, where signal integrity is paramount.

Rubber cables possess a natural ability to dampen vibrations and absorb mechanical shocks, making them suitable for environments characterized by substantial oscillations. Industries like transportation and heavy machinery benefit from this attribute, as it prevents cable wear and signal deterioration.

Furthermore, rubber cables often feature water-resistant properties, making them suitable for use in damp or aquatic environments. This quality is particularly useful in outdoor installations and maritime applications, where protection against water-induced vulnerabilities is essential.

In conclusion, rubber cables represent a harmonious fusion of flexibility and durability, making them a valuable asset in various industries. Their unique ability to withstand a wide range of challenges, including harsh environments, chemical exposure, and mechanical stress, underscores their significance. Rubber cables continue to shape the landscape of electrical cabling by providing a reliable solution that thrives in demanding and dynamic conditions.