[email protected]

[email protected]

+86 181-5747-1135

China Automotive Wire Manufacturers wholesale Automotive Wire Factory

+86 181-5747-1135

China Automotive Wire Manufacturers wholesale Automotive Wire Factory

Established in 1998, Zhejiang Jiahui Wire And Cable Co.,Ltd is a professional China Automotive Wire Manufacturers. To provide customers with best service and guarantee products quality, we are using advanced ERP, MES and SAP for all incoming and outgoing data management. As a professional wholesale Automotive Wire Factory, Our factory devotes to producing Automotive Wire, automotive wire, power cable and high temperature wire etc. We also get certification of UL,CE,VDE,TUV,SAA,CCC,GS etc. and all our products comply with ROHS and REACH environment standard.

More than 22 years of industry experience

Covers an area of 30,000 square meters

More than 200+ employees

Our annual production capacity is over 500,000km/year.

High Performance Production Machine,7S Site Management , Precise Laboratory Equipment

VDE H05SJ-K Fiberglass Silicone Wire is a high-performance electrical connection wire. Its excellent insulation and high temperature resistance have s...

Insulation and sheath materials: Solar cables usually use high-quality insulation and sheath materials, which have excellent waterproof properties. Fo...

ABS has high strength and hardness, and can withstand certain external forces and pressures, so it is suitable for application scenarios that require ...

This multi-core armored cable (CMX, CMR, CMP) is widely used in multiple fields and specific application scenarios due to its different fire ratings a...

Compared with other types of winding wires, wire-wrapped stranded enameled wire has the following significant advantages: Can balance the magnetic flu...

Compared with other power cords, this flexible power cord has the following advantages or characteristics: High flexibility: The design of the flexibl...

Efficiency on the Road: Exploring the Latest Advancements in Automotive Wire Design

In the realm of modern automotive engineering, the relentless pursuit of efficiency remains a driving force. From the heart of a vehicle’s powertrain to its intricate safety mechanisms, the effectiveness of the underlying electrical systems forms the core of its performance. As the automotive landscape advances, it becomes imperative to explore the forefront of progress in automotive wire design—an often overlooked yet crucial factor that underpins the efficiency of vehicles on the road.

One of the pivotal shifts in automotive wire design revolves around the choice of materials. Engineers are increasingly turning to lightweight yet remarkably strong options, such as aluminum conductors. Departing from the conventional use of copper, this innovation not only reduces the overall weight of the vehicle but also plays a significant role in bolstering fuel efficiency and overall maneuverability. The resultant lighter load necessitates less energy for acceleration and sustained motion, translating into an appreciable enhancement in fuel economy.

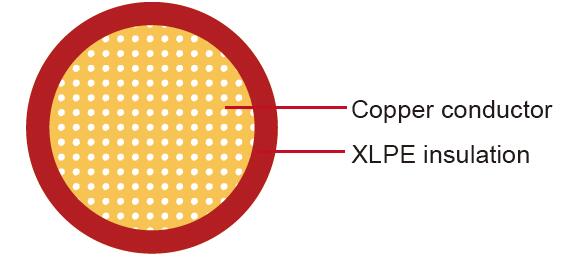

The evolution of automotive wire design is closely intertwined with the pursuit of minimized electrical resistance. This pivotal goal is achieved through the refinement of wire coatings and insulating materials, culminating in a notable reduction in energy loss and the generation of heat. By allowing a higher proportion of the electrical energy produced by the vehicle’s power source to effectively reach its intended destination, this advancement results in a comprehensive elevation of the system’s overall efficiency.

In an era defined by digital prowess, modern vehicles have emerged as intricate hubs of sensors, electronic components, and intricate communication networks. Smart wiring systems represent a transformative innovation that seamlessly melds data communication with power distribution. This sophisticated orchestration enables precise control and holistic management of a vehicle’s multifaceted functions. The result is an intricate dance of energy optimization, where power flow is dynamically tailored to real-time demands, ushering in an unprecedented era of efficiency.

At the heart of efficiency lies the unassuming connector—a linchpin that facilitates the seamless transmission of power and data within the intricate web of a vehicle’s systems. In the vanguard of connector design, the emphasis is squarely on reducing resistance and enhancing conductivity. These refined connectors serve as guardians of energy conservation, mitigating energy losses and ensuring steadfast electrical connections, which are pivotal for both propulsive and safety systems.

The surge of electrification in the automotive sphere has thrust high-voltage systems into the limelight. This realm is masterfully navigated through advanced wire design, ensuring the efficient distribution of high-voltage power to various vehicle components. This orchestration encompasses elements such as high-voltage battery systems, the rhythmic hum of electric drivetrains, and the sprawling canvas of charging infrastructure—a narrative where wiring efficiency reigns supreme.

Embedded within the crucible of efficient automotive wire design lies an unwavering commitment to durability and reliability. Wires and cables are endowed with the resilience to weather environmental fluctuations, vibrations, and the relentless march of time. These stalwart materials and insulation techniques form the backbone of unwavering performance, securing efficiency and safety as steadfast companions.